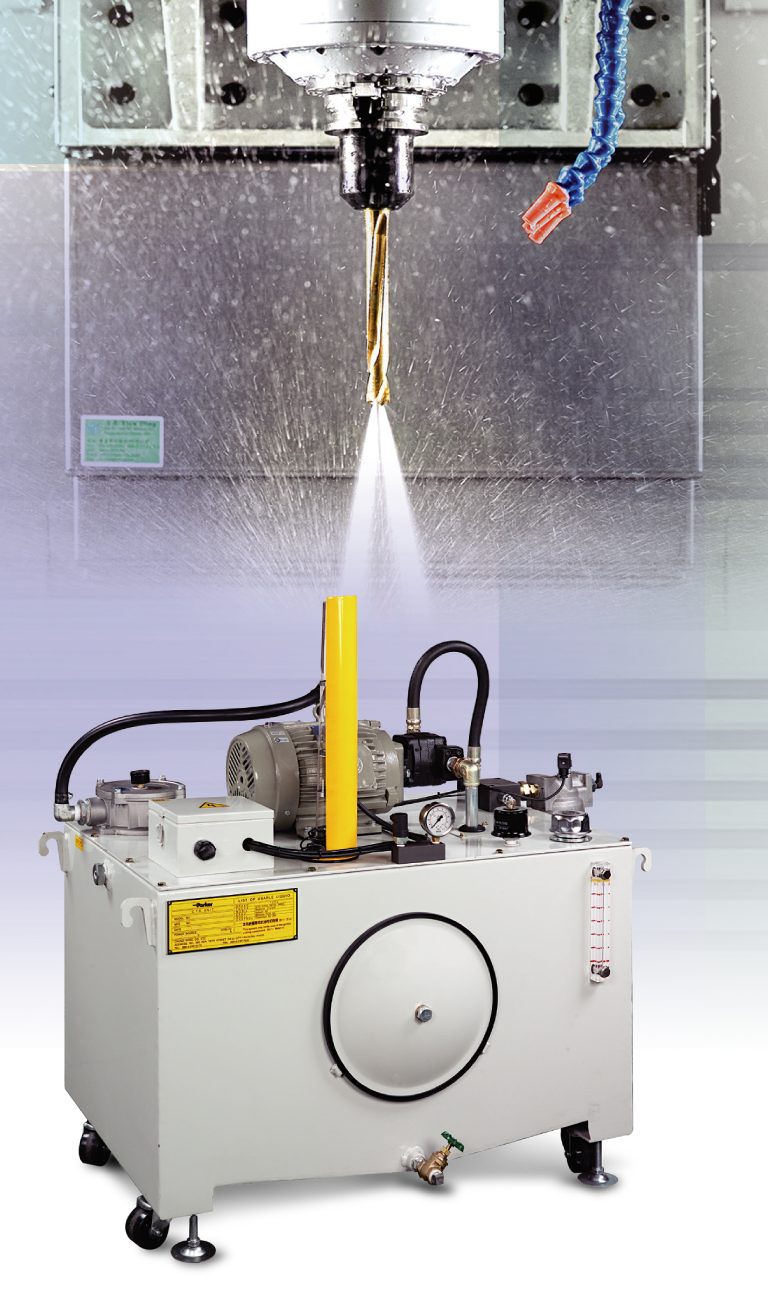

COOLANT-THROUGH-SPINDLE (CTS) 20-70 BAR (Optional)

Coolant-Through-Spindle provides coolant directly to the machining process through the center of the spindle. CTS may extend the life of the cutting tool and improve the evacuation of chips, especially when used for deep hole drilling and pocket milling.

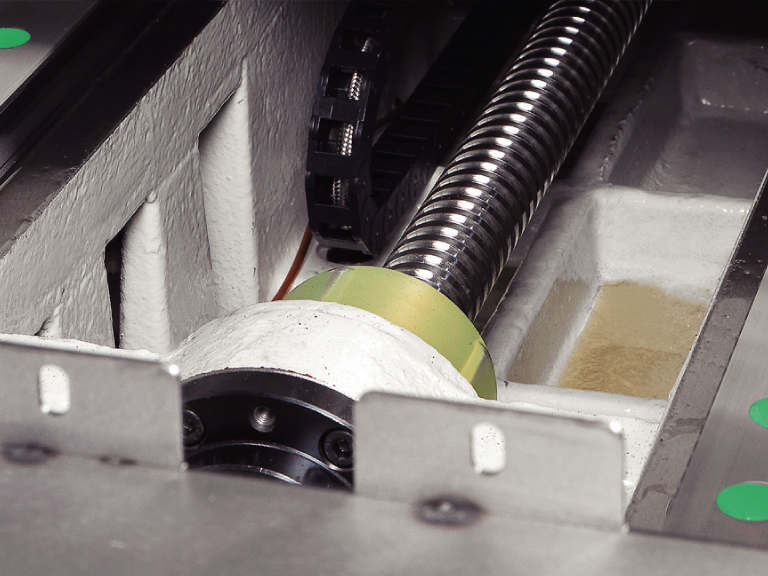

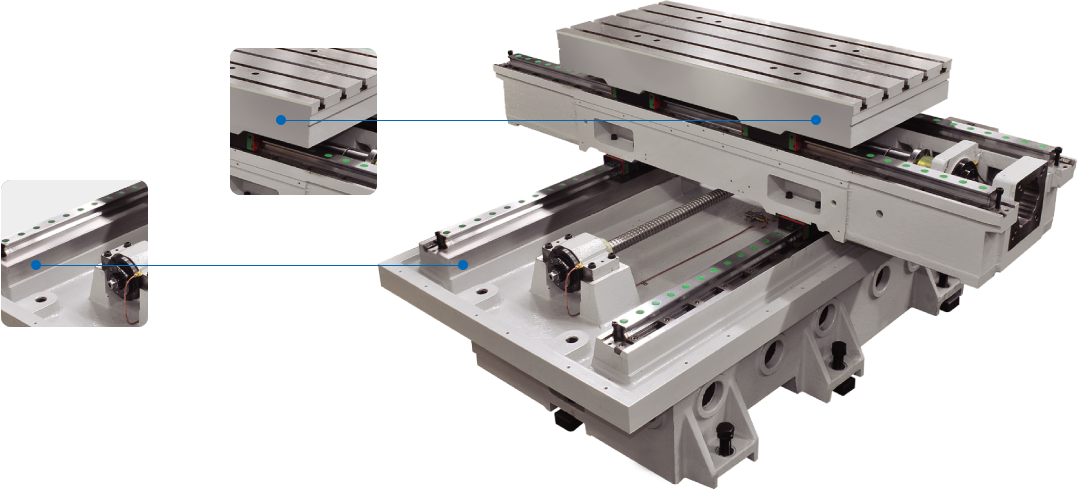

Ø63mm EXTRA LARGE BALLSCREW

Finetech's model 1890 and larger use ø63mm ball screws to handle heavier cutting and table loads while still providing smooth motion.

SPINDLE CHILLER ( Oil or Water )

The spindle chiller will help maintain a stable spindle temperature and will reduce the effects of thermal expansion of the spindle main shaft as well as extend the life of the spindle.

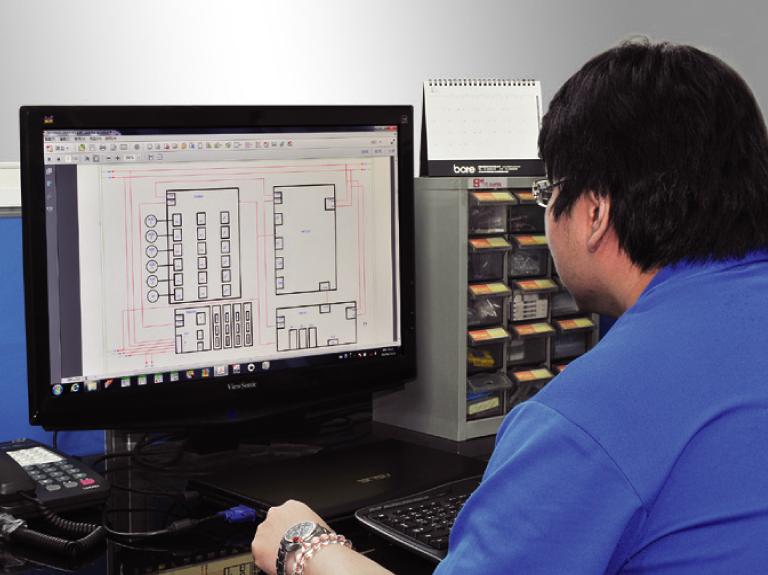

IN HOUSE CIRCUIT DESIGN

The Finetech R&D team can design both hardware and software components for the machine tools and allows for better quality control and quick response to customers requests.

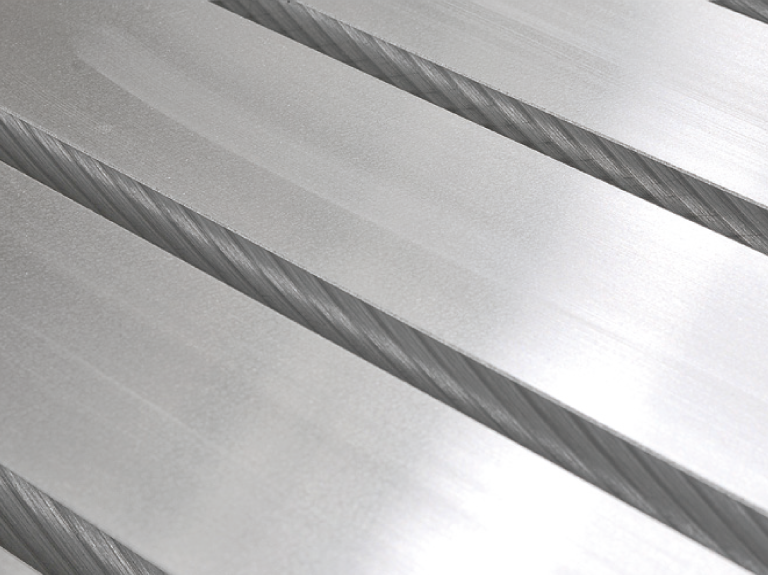

T-SLOT GRINDING

Each T-Slot is ground to a H8 tolerance to provide an accurate datum surface allowing for easy and precise machine setup.

LINEAR SCALE MOUNTING SURFACE

A precision ground surface can be added to each axis to allow for easy installation of linear scales by ensuring a straight and parallel surface.

Standard

- 8,000rpm belt type #40 taper spindle

- Spindle chiller

- Rigid tapping

- Spindle bearing air purge

- Z axis motor with brake system

- Guideway covers (X,Y,Z)

- Central lubrication system

- Fully enclosed machining area

- Wash down system

- Safety Door

- Mechanical oil/coolant separator

- LED work light

- Heat exchanger for electrical cabinet

- Coolant pump

- Spindle coolant nozzle system

- Auxiliary coolant gun

- Cutting air blast

- Auxiliary air gun

- Tool kit

- 3-color beacon light

- Leveling blocks & bolts

- Auto interrupt & power off system (M30)

- Portable hand wheel

- CNC control manuals, Operation manual, Maintenance manual

- Inspection report (CD format)

Optional

- Coolant Through Spindle (20-70Bar)

- Paper-type filter for CTS system

- Linear scale

- Programmable cutting coolant nozzle

- Oil mist coolant system

- Oil mist collector

- Chain type chip conveyor with chip cart

- Screw type chip auger with chip cart

- Laser type tool length measurement system

- Contact type tool length measurement system

- Workpiece measurement kinematic system

- 4th axis rotary table

- 4th/5th axis tilt/rotary table

- CE Certification

- Disk type oil Skimmer

- Air conditioner for electrical cabinet

- Transformer

- Jager high performanec spindles

- Mitsubishi M80, M830

- Fanuc 0iMF, 31i

- Siemens 828D, 840D

- Heidenhain TNC620, iTNC640

- Fagor